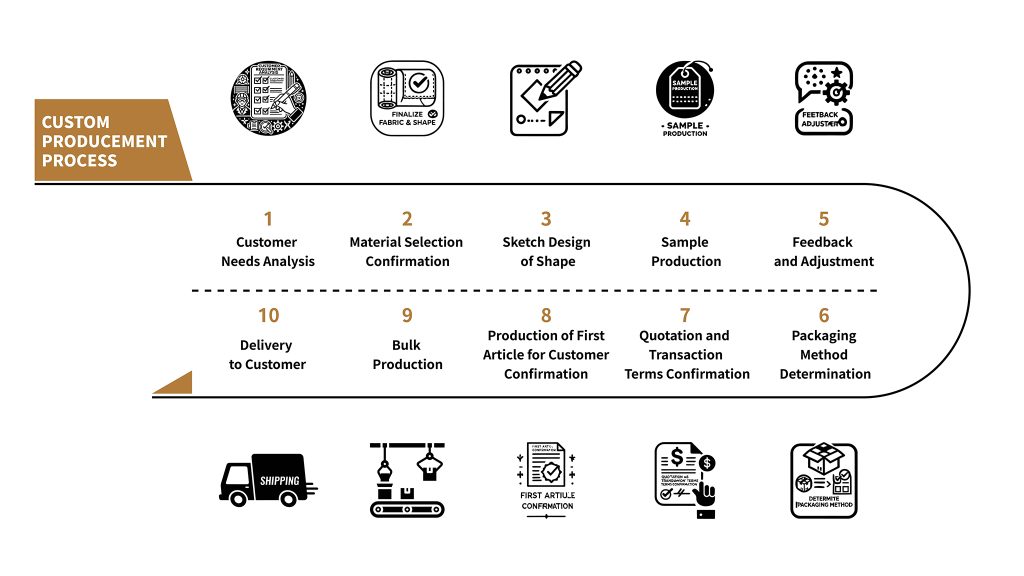

Development and Manufacturing Project Process

Development and Manufacturing Project Process

1 . Client Needs Analysis

Understand specific requirements for material shape, size, and cutting details.

2 . Confirm Suitable Material

Provide various material options to meet specific filtration needs.

3 . Sketch Design Shape

Design team creates initial shape sketches based on client requirements.

4 . Sample Production

Produce shape samples for client testing of material suitability and filtration effectiveness.

5 . Feedback and Adjustments

Adjust material shape and function based on client feedback.

6 . Final Material and Shape Confirmation

Confirm final material and shape design.

7 . Determine Packaging Method

Decide on appropriate packaging method based on client needs and product characteristics.

8 . Quotation and Terms Confirmation

Provide final quotation, including material, custom shape, and packaging costs, and confirm transaction terms.

9 . Material and Packaging Inspection

Ensure all production and packaging materials meet quality standards.

10 . Client Confirmation of First Production

Produce initial piece for client’s final confirmation to ensure bulk production meets requirements.

11 . Bulk Production

Conduct mass production based on client-approved initial piece.

12 . Delivery to Client

Deliver final products to client on time after production completion.