Non-woven fabrics are versatile materials with a wide range of applications across various industries. Unlike traditional textiles woven from yarn, these materials are created by bonding fibers directly together. This unique process results in strong, flexible fabrics used in everything from coffee filters to medical gowns. Let’s explore 13 examples that showcase the versatility and importance of non-woven fabrics in today’s world.

1. Beverage Filtration Accessories

Non-woven fabrics have revolutionized the beverage industry, serving as the cornerstone of filtration processes for a wide array of beverages. From the delicate infusion of tea to the robust brewing of coffee and the complex filtration needs of commercial beverage production, non-woven filters are indispensable. These versatile materials ensure optimal liquid flow while effectively trapping impurities such as coffee grounds, tea leaves, and other particulates. Their applications extend beyond traditional brewing methods, encompassing juice clarification, wine filtration, and even the production of alcoholic spirits. The customizable nature of non-woven fabrics allows for precise pore size control, enabling tailored filtration solutions for specific beverage types and quality standards. For instance, coffee filters, a specialized type of non-woven filter, are designed to capture the finest coffee grounds, ensuring a clean and flavorful cup.

2. Surgeon Gowns and Masks in Healthcare

In the high-stakes world of healthcare, non-woven fabrics are indispensable for patient and staff safety. Surgeon gowns and masks constructed from these materials offer a formidable barrier against contamination, playing a pivotal role in preventing the spread of infections. Their lightweight yet impermeable nature has made them synonymous with healthcare safety.

As a company dedicated to advancing medical textiles, Yiting is proud to have developed “Waterproof and Breathable Era Paper“, a groundbreaking innovation in non-woven materials. This new material represents a significant leap forward, transitioning from traditional PP or SMS structures to more sophisticated composite materials. Our ongoing research and development not only enrich the variety of non-woven fabrics but also enhance their performance, setting new standards in medical textiles. PaperPlus combines the best of both worlds : the strength and durability of non-woven fabrics with the lightweight and sustainable properties of paper.

Given the continuous advancements in non-woven technology, it is reasonable to anticipate an even greater role for these materials in healthcare. As we at Yiting continue to push the boundaries of innovation, non-woven fabrics are poised to make even more substantial contributions to human health.

Read more : Yiting Medical Face Masks.

3. Versatile and Sustainable Applications in Agriculture

Agricultural non-woven fabric has become indispensable in modern agriculture, offering a wide range of applications and promoting sustainable practices. As crop covers, these materials shield plants from adverse weather conditions, pests, and excessive sunlight, enhancing crop quality and productivity. Non-woven fabrics are also utilized in soil erosion control, weed prevention, and as substrates for hydroponics. Their versatility and durability, coupled with their eco-friendly attributes, make them a valuable asset to farmers seeking to optimize their yields while minimizing their environmental footprint.

4. Eco-Friendly Packaging

The shift towards sustainability has driven a surge in demand for eco-friendly packaging alternatives. Non-woven fabrics have emerged as a prime choice, offering a durable, aesthetically pleasing, and environmentally responsible solution. Replacing traditional packaging materials, non-woven fabric packaging options like Non-woven Fabric Drink Bags and Non-woven Mesh Carry Bags are gaining popularity. These reusable packages align perfectly with the growing eco-consciousness among consumers, making them a preferred choice in today’s market.

5. Kitchen Essentials and Cleaning Tools

Non-woven fabrics have found a practical and hygienic application in kitchenware. Sink strainer bags made from non-woven materials effectively capture food particles, preventing clogs and facilitating easy disposal. Similarly, non-woven steamer liners protect steamers from residue and food particles, ensuring efficient cleaning. In the realm of oil and grease management, oil-absorbing filter cloths made from non-woven fabrics are highly absorbent and durable, making them ideal for cleaning up spills and maintaining kitchen hygiene.

6. Personal Care and Home Organization

In the realm of personal care and home organization, non-woven fabrics have become indispensable. , crafted from soft, breathable PP composite non-woven material, provide a comfortable and effective barrier that protects makeup from smudging while trying on clothes. These covers are not only popular among high-end brands, especially in Japan, but also enhance customer satisfaction by preventing makeup stains on new garments. Additionally, versatile non-woven dust bags offer practical storage solutions, safeguarding various items from dust and scratches. non-woven protective covers also help maintain the cleanliness and longevity of furniture and electronics, ensuring their continued aesthetic appeal.

7. Food Packaging and Preservation

8. Disposable Wipes and Cleaning Cloths

Non-woven wipes and cleaning cloths make everyday cleaning tasks more efficient and hygienic. They are soft, absorbent, and durable, effectively picking up dirt, dust, and spills. These products are used in homes, healthcare facilities, and industries, providing a convenient and sanitary cleaning solution.

9. Absorbent Hygiene Products

In the realm of personal hygiene, non-woven fabrics are at the forefront of innovation. Their unique properties—softness, safety, and superior absorption—make them ideal for products such as diapers, feminine hygiene items, and adult incontinence products. These materials ensure comfort and reliability for users, a testament to the ongoing advancements in non-woven technology.

10. Insulation and Filtration in the Automotive Sector

Non-woven fabrics have found a multitude of applications within the automotive industry, particularly in insulation and filtration. These materials provide essential soundproofing and thermal insulation, enhancing the comfort and efficiency of vehicles. Furthermore, they are integral to air filtration systems, which ensure that both the vehicle’s cabin and engine are supplied with clean, uncontaminated air, contributing to the longevity and reliability of the vehicle.

11. Home Textiles and Furnishings

The comfort and durability of home furnishings owe much to the incorporation of non-woven fabrics. These materials, often used as backing for carpets or linings for upholstery, enhance the longevity and resilience of household textiles. The plushness and structure provided by non-wovens make them essential to creating the inviting, comfortable environments we associate with home.

12. Innovative Building Materials

The construction industry has long benefited from the use of non-woven fabrics. As effective insulators and house wraps, these materials play a critical role in enhancing a building’s thermal efficiency and protecting it from moisture and mold. Their contribution to the durability and energy efficiency of buildings is indispensable, ensuring structures that are both resilient and sustainable.

13. Interfacing in Apparel Manufacturing

The sharp lines of a well-tailored dress shirt or the structured elegance of a designer handbag are often achieved through the use of non-woven interfacing. This material, hidden within the seams, provides the form and structure necessary for garments and accessories to maintain their shape and aesthetic. In the world of fashion, where precision and quality are paramount, non-wovens are a key ingredient in the creation of high-end apparel.

Yiting : A Trailblazer in OEM/ODM Non-Woven Fabric Innovation

Yiting stands at the vanguard of non-woven fabric innovation. We are more than mere manufacturers; we are architects of ingenious solutions meticulously tailored to diverse industrial demands. As a preeminent OEM/ODM collaborator, we forge partnerships that propel businesses towards unparalleled success through exceptional product offerings.

Our state-of-the-art infrastructure empowers us to produce non-woven fabrics of unparalleled quality, exceeding the most stringent benchmarks. Yet, our capabilities extend far beyond production. We are steadfastly committed to sustainability and operational efficiency, ensuring each product embodies our pursuit of perfection.

Case Studies : Yiting’s Expertise in Non-Woven Fabric Solutions

1. Enhancing Coffee Filtration

A prominent coffee manufacturer was facing challenges with their filtration process, including inconsistent product quality and the presence of fine grounds in the final brew. Yiting was tasked with developing a solution to elevate their coffee filtration standards.

Leveraging our deep understanding of non-woven fabric technology, we engineered a specialized filtration system. Our advanced materials effectively captured fine coffee particles without compromising the flavor or aroma. This resulted in a significant improvement in product consistency and a reduction in waste.

2. Advancing Personal Protective Equipment

Yiting has been dedicated to developing personal protective equipment for many years. During the COVID-19 pandemic, when the global demand for high-quality masks surged, Yiting was proud to contribute to the world by continuously producing and developing a range of high-performance masks that meet international standards.

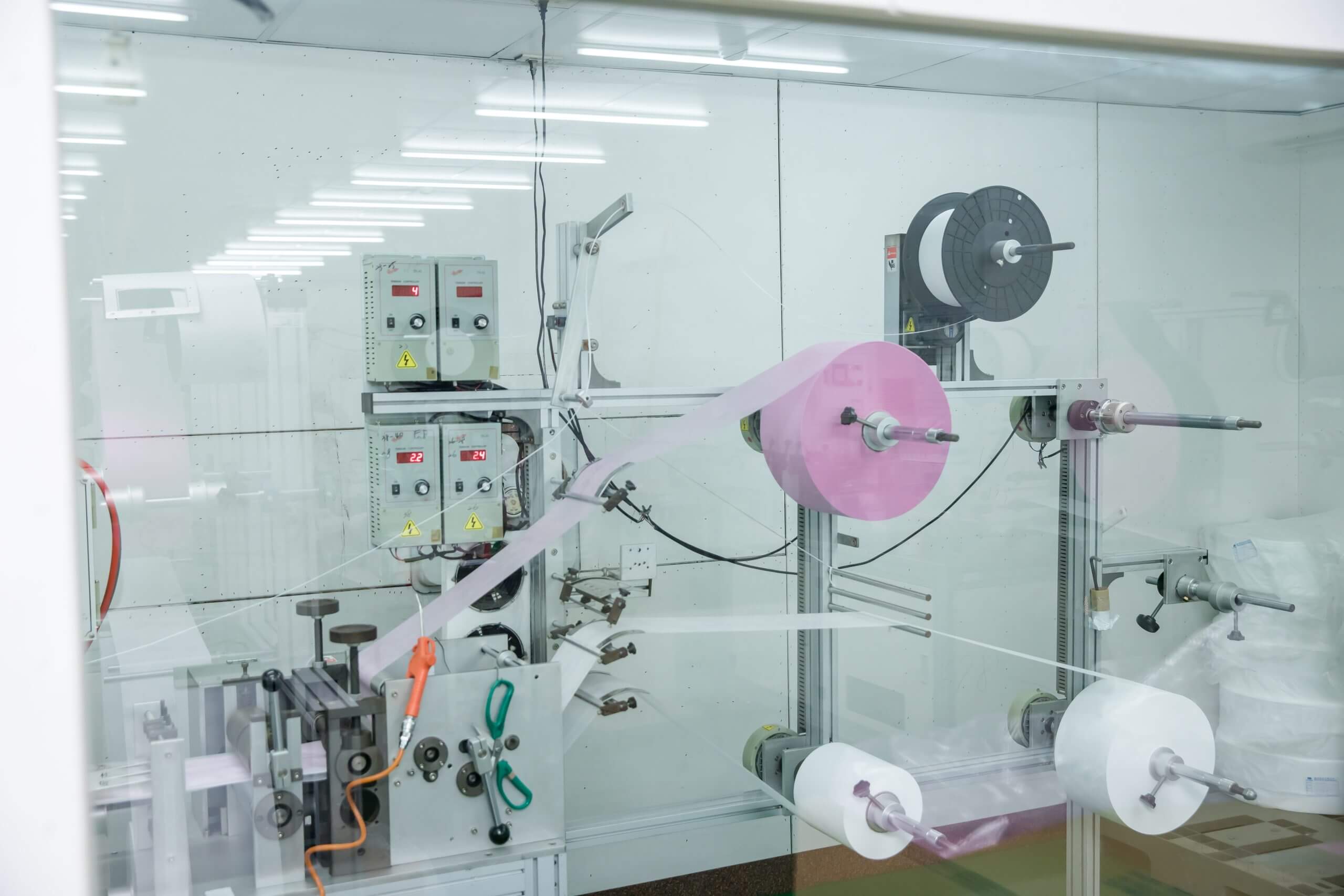

- Material Selection: Yiting possesses a complete non-woven fabric production line, enabling us to have full control over every aspect of mask production, from raw material development to finished product manufacturing. Our selected non-woven fabric materials not only meet international standards but also offer superior filtration performance and comfort. Through vertical integration, we ensure consistent product quality and can quickly respond to market demands.

- Production Process: We established a rigorous quality control system, with every step from raw material procurement to finished product shipment undergoing thorough inspection.

- Product Diversification: We offer a wide variety of mask styles, sizes, and colors to cater to diverse consumer needs.

- Customization: We provide customized mask design services for businesses and individuals to meet specific requirements.

- Increased Production Capacity: With an annual production capacity exceeding 105 million pieces, we can supply the market quickly and stably.

These case studies demonstrate Yiting’s ability to provide innovative and effective non-woven fabric solutions. Our deep industry knowledge and technical expertise allow us to address complex challenges and deliver exceptional results. Want to learn more about how non-woven fabrics can benefit your business? Contact Yiting today to discuss your project.